Mapping 4,000 global industrial automation projects: Where Siemens, Emerson, Rockwell Automation, ABB, and Schneider Electric place emphasis

In short

- Enterprise spending on industrial core value chain software and OT hardware is poised to surpass $350 billion by 2030 as manufacturers increasingly digitalize their businesses, according to recent IoT Analytics research.

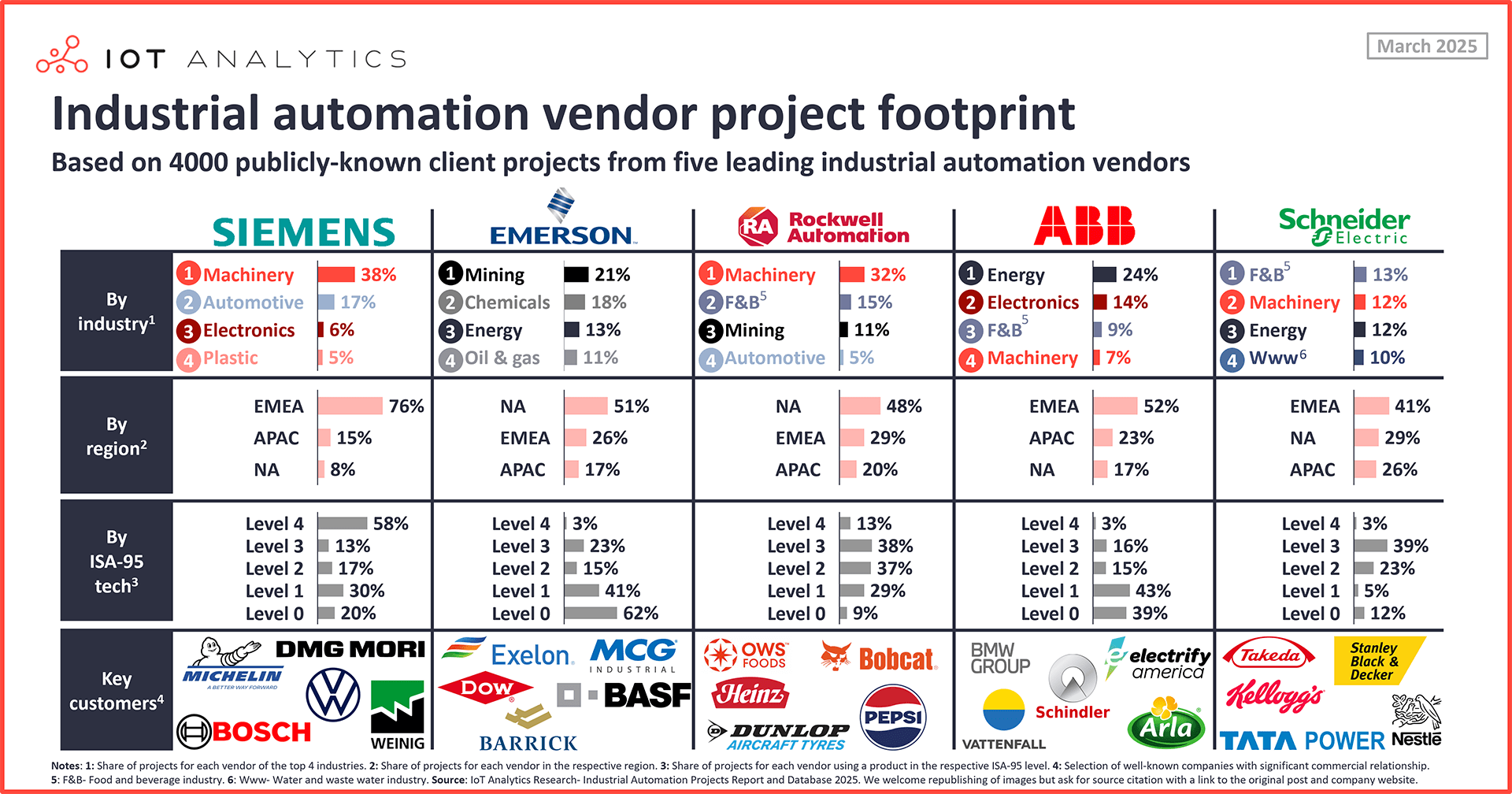

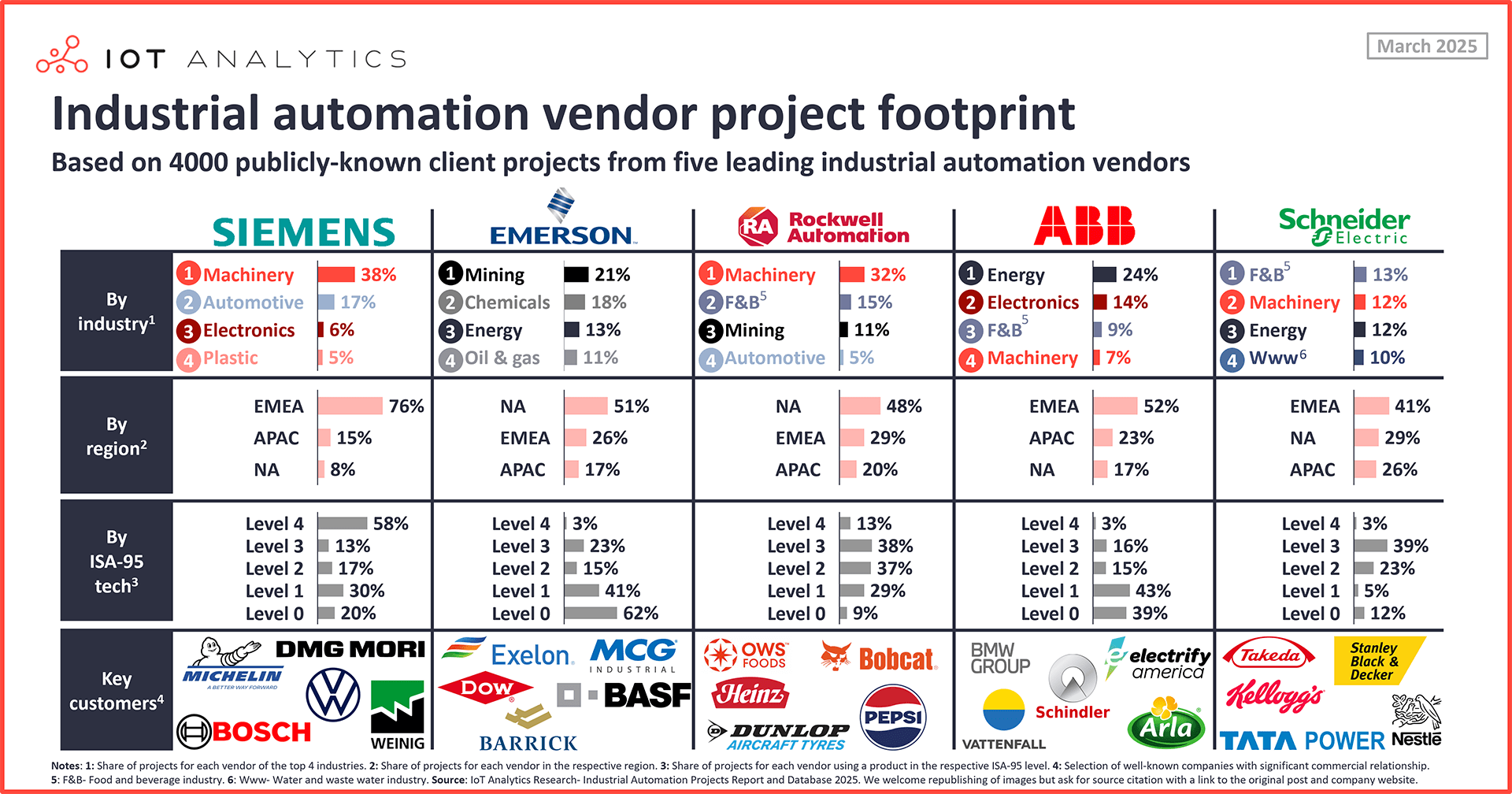

- Analysis in IoT Analytics’ 105-page Industrial Automation Projects Report and Database 2025—based on over 4,000 publicly shared case studies—reveals distinct industrial, regional, and technological footprints from 5 of the leading industrial automation vendors: Siemens, Emerson, Rockwell Automation, ABB, and Schneider Electric.

- Siemens’ case studies showcase projects in the machinery and automotive segments and in Europe the most; Emerson’s and Rockwell Automation’s studies have the highest share of projects in North America; ABB’s studies present a significant presence in energy and electrical projects; and Schneider Electric’s studies highlight the food and beverage industry the most.

Why it matters?

- For industrial automation vendors: An analysis of a company’s own and the competitor’s customer case studies allows for both an evaluation of a company’s potential strengths as well as the current marketing focus.

- For industrial automation adopters: An understanding of a vendors’ customer footprint may be an influencing factor for future investments and vendor choice.

About IoT Analytics’ industrial automation market coverage

Insights in this article are from IoT Analytics’ 105-page Industrial Automation Projects Report and Database 2025.

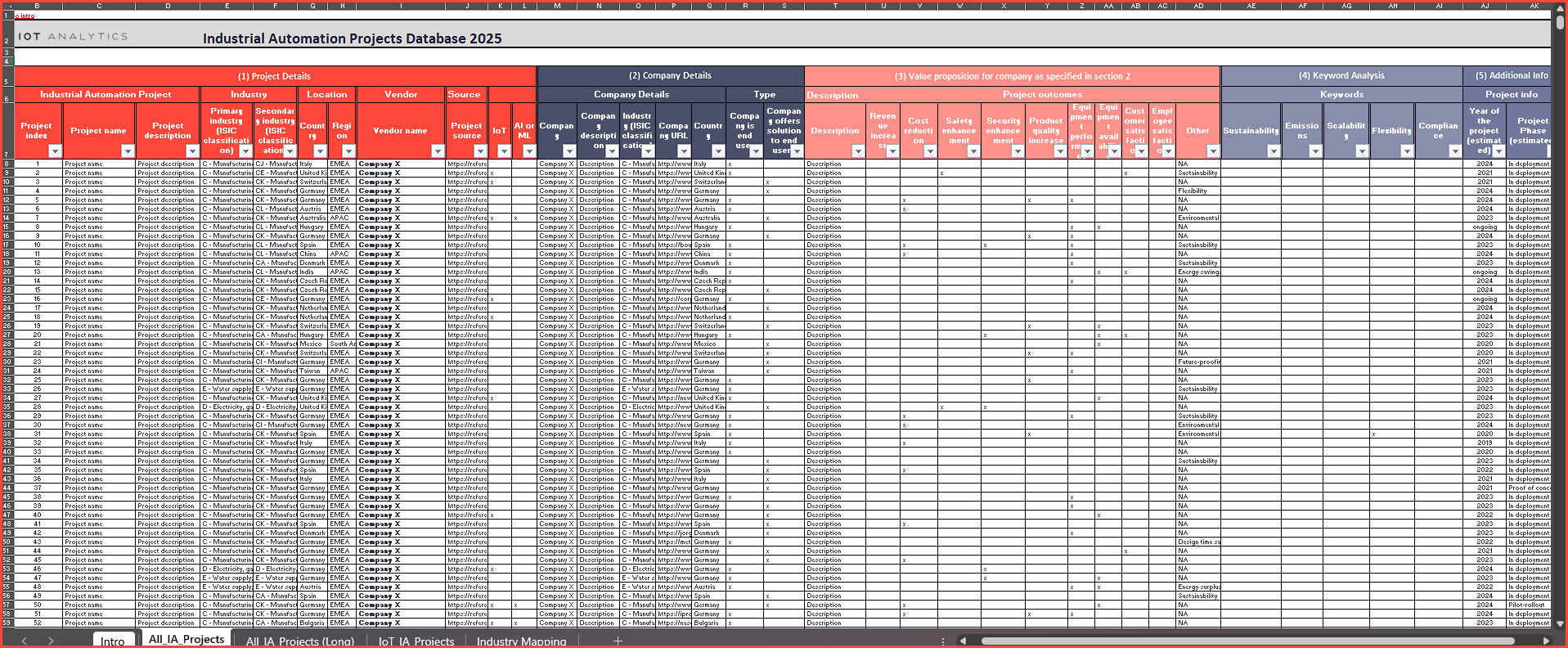

A structured repository of 4,200+ industrial automation projects from five of the leading vendors. It includes a 105-page report with analysis of the project landscape, a comparison of vendors, their products, share of AI and IoT.

Already a subscriber? View your reports here →

Industrial automation market snapshot

Industrial automation propelling OT software market growth. In 2024, businesses spent $252.6 billion on industrial core value chain software and OT hardware, and this figure is projected to surpass $350 billion by 2030, according to recent IoT Analytics research into industrial software. Behind these figures are thousands upon thousands of past and ongoing digitalization (and industrial automation) projects as manufacturers move to modernize their factories and streamline their operations.

Analysis of over 4,000 project case studies gives insights into vendors’ areas of emphasis. IoT Analytics traditionally focuses on the intersection of industry and technology, right where industrial automation resides. As part of the ongoing research into industrial automation, the team has compiled a database of over 4,000 publicly shared customer projects from the websites of 5 leading industrial automation vendors: Siemens, Emerson, Rockwell Automation, ABB, and Schneider Electric.*

Analysis of these projects—found in the 105-page Industrial Automation Projects Report and Database 2025 (published February 2025)—provides an indication of not only where vendors are doing business, including areas of emphasis over the last 2 years when compared to each vendor’s total projects, but also what each company’s marketing team has chosen to publicly share and emphasize. Below, the team shares its insights into areas of emphasis for these vendors based on the customer projects, including:

- Industries (e.g., automotive, electronics, or oil and gas)

- Regional and countries

- Types of products used in the projects (across the tech stack: ISA-95 automation levels)

*Note: IoT Analytics tracks more than 30 industrial automation vendors in its various market reports and analyses but has limited the scope of this analysis to 5 of the leading vendors for now. IoT Analytics may increase the scope of the analysis to more vendors in the future if further analysis is appreciated.

Mapping over 4,000 global industrial automation projects

Siemens shared the most projects. Of the 4,000+ identified industrial automation projects, Siemens has the most with 45%, followed by Emerson at 28%. Approximately 44% of the projects involve discrete manufacturing automation, followed by 20% for hybrid manufacturing and 11% for process manufacturing. Among all the projects, ISA-95 Level 0 products appear the most at 38%, while Level 2 products appear the least at 19%.

For reference, the ISA-95 levels are defined as follows:

- Level 0 refers to the field functions that directly interact with the physical production environment, such as sensors, actuators, and process control devices.

- Level 1 focuses on automation, where data from the field is gathered and used to control and manipulate production processes, and includes the use of PLCs or DCSs.

- Level 2 involves monitoring and control systems that oversee automated processes, ensuring the correct execution of operations, including HMIs or panel PCs.

- Level 3 covers manufacturing operations management, which includes systems for production control, workflow management, and process optimization, such as MESs.

- Level 4 is concerned with business planning and logistics, integrating production planning, inventory management, and alignment with business strategies, such as ERP software.

Siemens

Siemens, based in Germany, is the world’s largest industrial automation company.

Customer footprint by the numbers

By industry

Siemens showcases an emphasis on machinery and equipment. Siemens’ largest customer base is in machinery and equipment (38% of its published projects), followed by automotive (17%) and electrical equipment (6%). When looking at the last two years, the share of Siemens’ projects in the machinery and equipment industry is 8 percentage points higher than the industry’s share across all years, indicating continued emphasis in this industry.

By region

EMEA is Siemens’ largest customer base regionally. 76% of Siemens’ published industrial automation projects are in Europe, the Middle East, and Africa (EMEA)—with 28% of its overall projects in Germany—making it the most EMEA-centric vendor of the 5.

By technology

Siemens mostly portrays ISA-95 Level 4 technology. 58% of Siemens’ projects incorporate ISA-95 Level 4 solutions, 78% of which are design and engineering tools, such as CAE tool Simcenter (39%) and CAD/CAM tool NX (21%). Meanwhile, 30% of its projects include ISA-95 Level 1 products, 76% of which involve industrial control devices, such as SIMATIC PLCs.

It is worth noting that Siemens has a sizable software portfolio. IoT Analytics analysis of the industrial software landscape places Siemens as the top earner along the core industrial value chain.

Selected key customers based on public projects

- Mercedes-Benz Group AG: In 2022, Siemens helped the Germany-based automotive manufacturer Mercedes-Benz Group transition from physical durability testing of new vehicles to digital simulations using Siemens’ design and engineering software solution Simcenter. This involved standardizing the durability process globally for the group, and according to Siemens, this project radically changed Mercedes-Benz’s durability engineering process from early development prototyping to CAE simulation.

- Michelin Group: In 2023,France-based tire company Michelin turned to Siemens for help in creating digital twins of its tire production machines to simulate the entirety of these machines during the engineering phases. The aim was to reduce the engineering, commissioning, and training timelines. The project entailed incorporating various automation technologies such as Siemens’ SIMATIC S7-1500 PLC, third-party PLCs, Siemens’ simulation platform SIMIT, robots from Japan-based automation and robotics companies Fanuc and Yaskawa, and Siemens’ simulation and virtual commissioning tool NX Mechatronics Concept Designer.

Emerson

Emerson Electric is a US-based industrial automation and engineering services company founded in 1890.

Customer footprint by the numbers

By industry

Emerson case studies show a heavy focus on process industries. Emerson’s largest customer base in its published projects is mining (21%), followed by chemicals (18%), energy (13%), and oil and gas (11%).

By region

North America is Emerson’s largest customer base regionally. Emerson has the highest concentration of its case studies based in North America at 51%. It appears that Emerson is starting to make some inroads into EU markets, as the share of Emerson’s EMEA-based projects over the past 2 years is 12 percentage points higher than the region’s share among all of Emerson’s projects in the database (26% share).

By technology

Emerson mostly showcases ISA-95 Level 0 technology. 62% of Emerson’s projects incorporate ISA-95 Level 0 solutions, 93% of which are sensors and field instruments. Of these sensors, 54% involve industrial measurement devices from Emerson’s Rosemount line, and 19% involve Micro Motion flow meters.

Key customers based on public projects

- BASF: In 2020, Emerson deployed CSI vibration analyzers and AMS Machinery Manager software at BASF Antwerp in Belgium to transition from time-based preventive maintenance to predictive maintenance. According to Emerson, the system enabled early detection of critical equipment issues, such as bearing cage problems and faults in slow-speed machinery, leading to significant cost savings (up to €10,000 from just one case of an avoided outage) and reduced downtime.

- Dow Chemical Company: Emerson helped US-based Dow Chemical implement Emerson’s Flexim FLUXUS G722 ST-HT clamp-on ultrasonic flow measurement system at its German subsidiary Dow Olefinverbund GmbH’s Schkopau chemical park to monitor steam flow into its medium-pressure steam network. According to Emerson, this non-intrusive technology enabled real-time steam measurement without pipeline modifications, ensuring continuous operation and reducing installation downtime.

Rockwell Automation

Rockwell Automation is a US-based provider of industrial automation and digital transformation technologies.

Customer footprint by the numbers

By industry

Rockwell Automation presents a strong focus on machinery and equipment. Rockwell’s largest customer base is in machinery and equipment (32% of projects), followed by food & beverage (15%).

By region

North America is Rockwell Automation’s largest customer base regionally. 48% of Rockwell Automation’s case studies are based on projects in North America. EMEA and APAC follow at 29% and 20%, respectively.

By technology

Rockwell Automation often showcases MOM and SCADA solutions. Rockwell Automation largely incorporates ISA-95 Level 3 and 2 products into its projects at 38% and 37%, respectively. Of the Level 3 products, 82% are MOM software solutions, such as Rockwell Automation’s manufacturing execution system Plex MES. Meanwhile, 52% of the Level 2 products are SCADA solutions, such as the company’s FactoryTalk View SE.

Selected key customers based on public projects

- OWS Foods: In 2023,OWS Foods, a US-based manufacturer of sauces, dressings, dry rubs, and other food additives, implemented Rockwell Automation’s Plex Supply Chain Planning system as a unified platform for demand forecasting, scheduling, and procurement, replacing manual processes and consolidating data from multiple sources. According to Rockwell Automation, OWS Foods achieved a 25% increase in forecasting accuracy and reduced customer lead times by 33%, enhancing operational efficiency and employee satisfaction.

- Dunlop Aircraft Tyres: In 2023, Dunlop Aircraft Tyres implemented Rockwell Automation’s Fiix CMMS and Asset Risk Predictor to transition from reactive to predictive maintenance strategies. According to Rockwell Automation, this integration enabled efficient maintenance scheduling, enhanced resource allocation, and early risk detection. Further, since implementation, Dunlop has experienced significant improvements in maintenance efficiency and reduced unplanned downtime.

ABB

ABB is a Switzerland-based electrification and automation company that specializes in electrification, motion, process automation, and robotics.

Customer footprint by the numbers

By industry

Energy and electrical infrastructure appear most. ABB’s largest customer base in its case studies are energy and electrical equipment, appearing in 24% and 14% of projects, respectively.

By region

EMEA is ABB’s largest customer base regionally. 52% of ABB’s case studies involve projects in EMEA, making these studies the second-most EMEA-centric of the 5 vendors. APAC and North America follow at 23% and 17%, respectively.

By technology

ABB emphasizes control devices and robotics in projects. 43% of ABB’s projects incorporate ISA-95 Level 1 products. 52% of these Level 1 inclusions involve control devices, such as ABB’s System 800xA controllers. Notably, 45% of ABB’s Level 1 product inclusions (and 17% of its overall projects) involve robots, such as its IRB series of articulated robots and YuMi and GoFa series of collaborative robots.

Selected key customers based on public projects

- BMW Group: In 2022, ABB deployed GoFa collaborative robots at BMW’s Steyr, Austria, engine plant to automate the handling of connecting rods between conveyors, reducing production stoppages and improving efficiency. ABB states that since implementation, the robots have eliminated unplanned downtime during changeovers, enhancing workflow reliability and worker safety.

- Schindler: In 2019, ABB collaborated with Switzerland-based Schindler Elevator to develop the Robotic Installation System for Elevators (Schindler R.I.S.E), an autonomous robot designed to drill holes and install anchor bolts in elevator shafts. Utilizing ABB’s IRB 2600 industrial robot, the system automates repetitive and physically demanding tasks. According to ABB, this solution has enhanced precision and safety during elevator installations.

Schneider Electric

Schneider Electric is a France-based energy management and automation company.

Customer footprint by the numbers

By industry

Food and beverages are showcased the most. The food and beverages industry has the most share of Schneider Electric’s case studies at 13%, followed by machinery and energy at 12% share each. Schneider Electric is the only vendor of the 5 that does not have an industry with over 20% project share of its case studies.

By region

EMEA leads in regional customer base. EMEA is the largest regional customer base in Schneider Electric’s case studies at 41%. North America and APAC follow at 29% and 26%, respectively.

By technology

ISA-95 Level 3 products take the largest share of Schneider Electric’s case studies. 39% of Schneider Electric’s published projects included ISA-95 Level 3 products, primarily from its EcoStruxure platform, including industrial automation and control system EcoStruxure Plant and asset performance management tool EcoStruxure Asset Manager.

Selected key customers based on public projects

- Takeda Pharmaceuticals: In 2022, Schneider Electric implemented its EcoStruxure Building Operation, AVEVA System Platform, and Modicon controllers at Takeda’s Singapore facility to automate energy management across its operations. This integration resulted in a 15% energy surplus, enabling Takeda to improve energy efficiency while supporting sustainability goals and reducing operational costs.

- Nestlé: In 2020, Swiss-based multinational food and beverage company Nestlé transitioned its Nescafé plant in Toluca, Mexico, from traditional to condition-based maintenance by implementing Schneider Electric’s EcoStruxure digital platform. This shift involved equipping electrical panels, transformers, and switchgear with sensors, enabling 24/7 remote monitoring and management. Since implementation, the plant has avoided 5 major incidents, resulting in estimated savings of $2 million and enhanced operational reliability.

Analyst takeaway: The share of AI-based industrial automation projects is low… for now

What does not stand out in the analysis of the 4,000+ industrial automation projects is AI. According to the Industrial Automation Projects Report and Database 2025, only 3% of projects involved AI, with Schneider Electric holding the largest share of AI among its projects at 7%. While AI is not new, interest in the technology has only boomed in the last few years. Widespread AI deployment and value generation remains to be seen, but there is no question that manufacturers are increasingly turning to industrial automation to help solve operational inefficiencies and skill/labor gaps. AI will be the natural next step in the coming years, and companies are taking notice. CEOs have made AI the top non-economic topic during earnings calls in 2024, and discussions around AI applications, including AI-based process automation and predictive maintenance, have increased. As AI-based projects move past the proof-of-concept stages and measurable outcomes become apparent, IoT Analytics expects vendors to tout these successes and increase the share of AI-based industrial automation and digitalization projects found in their case studies.

Disclosure

Companies mentioned in this article are used as examples to showcase the trends discussed. No company paid or received preferential treatment in this article, and it is at the discretion of the analyst to select which examples are used. IoT Analytics makes efforts to vary the companies and products mentioned to help shine attention to the numerous IoT and related technology market players.

It is worth noting that IoT Analytics may have commercial relationships with some companies mentioned in its articles, as some companies license IoT Analytics market research. However, for confidentiality, IoT Analytics cannot disclose individual relationships. Please contact compliance@iot-analytics.com for any questions or concerns on this front.

More information and further reading

Are you interested in learning more about the industrial automation projects?

Already a subscriber? View your reports here →

Related articles

You may also be interested in the following articles:

- 8 notable developments in software-defined manufacturing

- The industrial software market landscape: 7 key statistics going into 2025

- IT/OT convergence: The 27 themes that define the future of industrial integration

Related publications

You may also be interested in the following reports:

- SPS Fair 2024: The Latest Industrial Automation Trends

- Industrial Software Landscape 2024–2030

- IT OT Convergence Insights Report 2024

- Industrial Connectivity Market Report 2024–2028

Subscribe to our research newsletter and follow us on LinkedIn to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports, including dedicated analyst time, check out the Enterprise subscription.

Leave a Comment